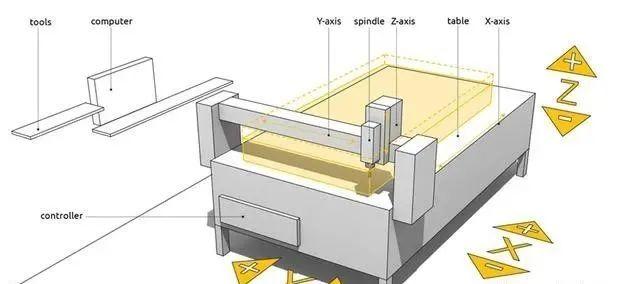

I-CNC machining ibandakanya ukusetyenziswa koomatshini bokulawula amanani ekhompyutheni (CNC) ukubumba kunye nokutshintsha ubungakanani bentwana, okanye i-workpiece, ngokususa ngokuzenzekelayo izinto.Ngokuqhelekileyo, izinto ezisetyenzisiweyo ziyiplastiki okanye isinyithi, kwaye xa ukususwa kugqityiwe, imveliso egqityiweyo okanye imveliso yenziwe.

Le nkqubo ikwabizwa ngokuba yi-subtractive production.Kwi-CNC machining, isicelo sekhompyutheni sisetyenziselwa ukulawula ukuhamba kwesixhobo somatshini.

Iindidi zezixhobo zomatshini eziqhelekileyo ze-CNC

Iinkqubo ze-CNC ze-machining ziquka ukugaya kunye nokujika okuqhelekileyo, okulandelwa kukugaya, ukukhutshwa kombane, njl njl.

Ukugaya

Ukugaya kukusetyenziswa kwesixhobo esijikelezayo kumphezulu womsebenzi, sihamba nge-3, 4 okanye i-5 axes.Ukugaya ngokusisiseko kukusikwa okanye ukuchetywa kwezinto zokusebenza, ukuvumela iijometri ezintsonkothileyo kunye namalungu achanekileyo ukuba zenziwe ngoomatshini ngokukhawuleza kwiintsimbi okanye i-thermoplastics.

Ukujika

Ukujika kukusetyenziswa kweleyile ukwenza iinxalenye ezineempawu zecylindrical.Umsebenzi ojikelezayo ujikeleza kwi-shaft kwaye uqhagamshelane nesixhobo sokuguqula ngokuchanekileyo ukwenza imiphetho ejikelezileyo, imingxuma ye-radial kunye ne-axial, i-grooves kunye ne-grooves.

Izinto ezilungileyo zeCNC machining

Xa kuthelekiswa noomatshini bemveli bezandla, umatshini weCNC ukhawuleza kakhulu.Ngethuba nje ikhowudi yekhompyutheni ichanekile kwaye ihambelana noyilo, imveliso egqityiweyo inokuchaneka okuphezulu kunye neempazamo ezincinci.

Ukwenziwa kwe-CNC yeyona ndlela ifanelekileyo yokwenza iprototyping ekhawulezileyo.Ingasetyenziselwa ukwenza iimveliso zokusetyenziswa kokuphela kunye namacandelo, kodwa ngokuqhelekileyo ineendleko ezisebenzayo kuphela kwivolumu ephantsi, imveliso yexesha elifutshane.

Multi-axis CNC machining

Ukugaya i-CNC kubandakanya ukususa izinto usebenzisa izixhobo ezijikelezayo.Nokuba i-workpiece ihlala imile kwaye isixhobo sihamba siye kwi-workpiece, okanye i-workpiece ingena kumatshini kwi-engile enqunywe kwangaphambili.Okukhona umatshini uneezembe ezininzi, kokukhona intsonkothe yaye ikhawuleza inkqubo yawo yokuyila.

3-axis CNC machining

I-Three-axis CNC milling ihlala yenye yezona nkqubo zidumileyo kwaye zisetyenziswa ngokubanzi.Kwi-3-axis machining, i-workpiece ihlala imile kwaye isixhobo esijikelezayo sisika ecaleni kwe-x, y, kunye no-z axes.Olu luhlobo olulula lwe-CNC machining oluvelisa iimveliso ezinezakhiwo ezilula.Ayifanelekanga ukwenza iijometri ezintsonkothileyo okanye iimveliso ezinamacandelo anzima.

Kuba iiasi ezintathu kuphela ezinokusikwa, umatshini unokucotha kune-CNC ezine okanye ezintlanu, njengoko i-workpiece inokufuneka ibekwe ngokutsha ngesandla ukuze ifumane imilo efunekayo.

4-axis CNC machining

Kwi-four-axis CNC milling, i-axis yesine yongezwa kwintshukumo yesixhobo sokusika, evumela ukujikeleza kwi-x-axis.Ngoku kukho iiasi ezine -x-axis, y-axis, z-axis kunye ne-axis (ujikelezo olujikeleze i-x-axis).Uninzi koomatshini be-CNC be-4-axis nabo bavumela i-workpiece ukuba ijikeleze, ebizwa ngokuba yi-b-axis, ukuze umatshini akwazi ukusebenza njengomatshini wokungqusha kunye ne-lathe.

4-i-axis CNC machining yindlela yokuhamba ukuba ufuna ukugrumba imingxuma kwicala leqhekeza okanye kumphezulu we-cylinder.Ikhawulezisa kakhulu inkqubo yomatshini kwaye inokuchaneka okuphezulu komatshini.

5-axis CNC machining

I-five-axis CNC milling ine-axis eyongezelelweyo yokujikeleza xa kuthelekiswa ne-CNC ye-four-axis.I-axis yesihlanu kukujikeleza kwe-axis ka-y, eyaziwa ngokuba yi-b-axis.Isixhobo sokusebenza sinokujikeleziswa kwabanye oomatshini, ngamanye amaxesha kuthiwa yi-b-axis okanye i-c-axis.

Ngenxa yokuguquguquka okuphezulu kwe-5-axis CNC machining, isetyenziselwa ukwenza iindawo ezichanekileyo ezichanekileyo.Njengamalungu ezonyango kumalungu enziweyo okanye amathambo, iindawo ze-aerospace, iinxalenye ze-titanium, iinxalenye zoomatshini be-oyile kunye negesi, iimveliso zomkhosi, njl.

Ixesha lokuposa: Sep-29-2022