Kwinkqubo yokusika, ngenxa yamandla okusika, udonga olucekeceke lulula ukukhubazeka, okubangela ukuba i-ellipse okanye "isinqe" ibe yinto encinci kunye neziphelo ezinkulu.Ukongezelela, ngenxa yokutshatyalaliswa kobushushu obuhlwempuzekileyo ngexesha lokulungiswa kweegobolondo ezinodonga oluncinci, kulula ukuvelisa i-thermal deformation, enzima ukuqinisekisa umgangatho wokulungiswa kweengxenye.Ezi nxalenye zilandelayo azinzima nje ukuzibamba, kodwa zikwanzima nokusetyenzwa.Ngoko ke, i-sleeve ekhethekileyo enodonga oluncinci kunye ne-shaft yokukhusela iya kuyilwa.

Puhlalutyo rosi

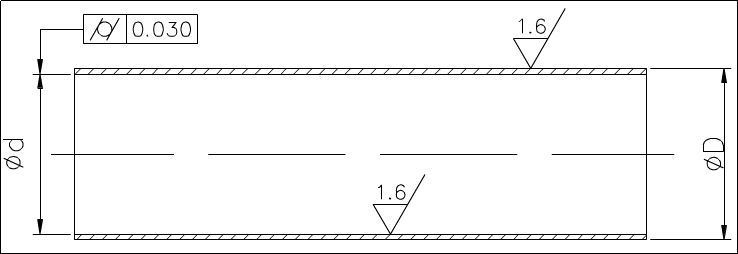

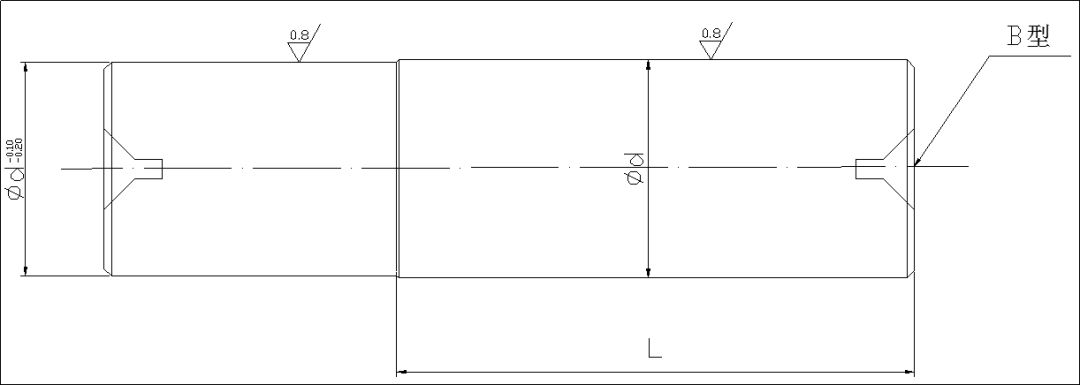

Ngokweemfuno zobugcisa ezinikezelwe kumzobo, i-workpiece icutshungulwa ngumbhobho wensimbi ongenamthungo, kunye nobunzima bomphezulu womgodi wangaphakathi kunye nodonga lwangaphandle nguRa1.6 μ m.Inokuqondwa ngokujika, kodwa i-cylindricity yomngxuma wangaphakathi ngu-0.03mm, efuna iimfuno eziphezulu kwiingxenye ezinqabileyo.Kwimveliso yobuninzi, inkqubo yenkqubo inzima ngolu hlobo lulandelayo: ukuvala - unyango lobushushu - ukuguqula ubuso bokuphela - ukuguquka kwesangqa - ukuguqula umngxuma ongaphakathi - ukuhlolwa komgangatho.

"Inner hole machining" inkqubo isitshixo ulawulo umgangatho.Kunzima ukuqinisekisa i-0.03mm cylinder xa usika umngxuma ongaphakathi weqokobhe ngaphandle kodonga olucekethekileyo lwe-cylindrical.

Itekhnoloji ephambili yokujika imingxuma

Ithekhnoloji ephambili yokuguqula imingxuma kukusombulula iingxaki zokuqina kunye nokususwa kwe-chip yezixhobo zokuguqula umngxuma wangaphakathi.Ukuze kuphuculwe ukuqina kwesixhobo sokuguqula umngxuma wangaphakathi, kufuneka kuthathwe la manyathelo alandelayo:

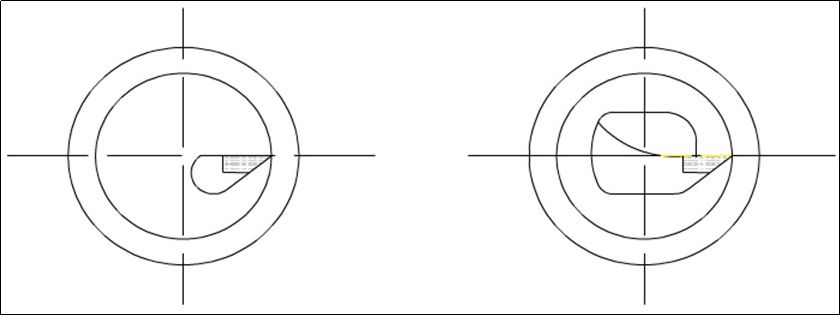

I-1) Ukwandisa indawo enqamlezileyo yesibambo sesixhobo kangangoko kunokwenzeka.Ngokuqhelekileyo, incam yesixhobo sokuguqula umngxuma wangaphakathi ibekwe ngaphezu kwesixhobo sokuphatha, ngoko ke indawo yecandelo lesixhobo sokuphatha isixhobo ingaphantsi kwe-1/4 yendawo yecandelo lomngxuma, njengoko kuboniswe kulo mfanekiso ulandelayo.Ukuba incam yesixhobo sokuguqula umngxuma wangaphakathi ibekwe kumgca ophakathi wesixhobo sokuphatha, indawo yecandelo lesixhobo somngxunya inganyuswa kakhulu, njengoko kuboniswe kulo mfanekiso ulandelayo.

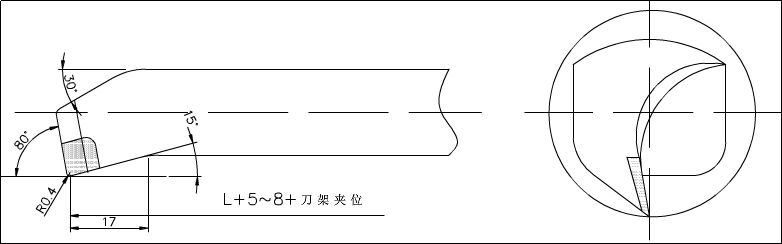

2) Ubude obude besixhobo sokuphatha buya kuba ngu-5-8mm ubude kunobude bomsebenzi womsebenzi kangangoko kunokwenzeka ukwandisa ukuqina kwesixhobo sokuphatha kunye nokunciphisa ukungcangcazela ngexesha lokusika.

Sombulula ingxaki yokususwa kwetshiphu

Ilawula ubukhulu becala indlela yokuhamba.Izixhobo zokujika ezirhabaxa zifuna ukuba itshiphu iqukuqelele phezulu ukuze yenziwe ngoomatshini (itshiphu yangaphambili).Ke ngoko, sebenzisa isixhobo sokuguqula umngxuma wangaphakathi ngokuthambekela komphetho olungileyo, njengoko kubonisiwe kulo mfanekiso ulandelayo.

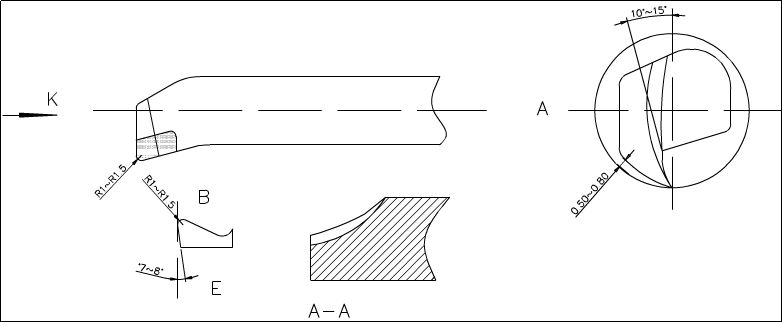

Kwinkqubo yokujika kakuhle, isikhokelo sokuhamba kwechip siyafuneka ukuthambeka itshiphu yangaphambili ukuya embindini (ukususwa kwetshiphu kwiziko lomngxuma).Ngoko ke, ingqalelo kufuneka ihlawulwe kwisalathiso sokusila somgca wokusika xa ulola isixhobo.Indlela yokususa itshiphu kufuneka ilandele i-arc ethambekele phambili.Njengoko kubonisiwe kulo mzobo ungezantsi, i-M-uhlobo lwangoku lwesixhobo sokuguqula i-alloy ye-YA6 inamandla okugoba, ukuxhathisa ukunxiba, ukuqina kwempembelelo, ukunamathela ngentsimbi, kunye nokumelana nobushushu.

Ngexesha lokugaya, ngokwe-arc processing (kunye ne-arc yesixhobo esisezantsi), i-angle yangaphambili ijikelezwe kwi-angle ye-arc ye-10-15 °, kwaye i-angle yangasemva i-0.5-0.8mm ukusuka eludongeni.I-angle ye-cutting edge ye-c yi-§ 0.5-1 kwindlela ye-k kunye ne-R1-1.5 kwindawo ye-B ecaleni kwe-chip edge.I-angle yesibini yangasemva ifanelekile ukugaya ukuya kwi-7-8 °.Inqaku lokusila i-AA kumda wangaphakathi we-E kwisangqa ukukhupha inkunkuma ngaphandle.

Pindlela yokukhwela

1) Izikhuselo ze-Shaft kufuneka zenziwe ngaphambi komatshini.Umsebenzi oyintloko womkhuseli we-shaft kukugubungela umngxuma wangaphakathi ojikayo we-sleeve enodonga oluncinci kunye nobukhulu bokuqala kwaye uyilungise ngamaziko angaphambili nangasemva, ukwenzela ukuba ikwazi ukucubungula isangqa sangaphandle ngaphandle kokuguqulwa, kwaye igcine umgangatho wokucubungula. kunye nokuchaneka kwesangqa sangaphandle.Ke ngoko, ukusetyenzwa kwe-shaft ekhuselayo likhonkco eliphambili le-casing-casing processing processing.

45 #carbon structural intsimbi engqukuva yokusetyenzwa kwe-embryo erhabaxa yokugcina i-shaft;Jikelezisa isiphelo sobuso, vula imingxuma esembindini emile okwe-B kuzo zombini iziphelo, wenze isangqa sangaphandle sibe rhabaxa, kwaye ushiye isibonelelo se-1mm.Emva kokunyangwa kobushushu, ukucima kunye nokufudumala, ukubunjwa kwakhona, kunye nokujika okulungileyo, isibonelelo se-0.2mm siya kugcinwa ukugaya.Umphezulu wedangatye otyumkileyo uya kunyangwa ngobushushu kwakhona ngobulukhuni be-HRC50, kwaye emva koko ucolwe ngegrinder yecylindrical, njengoko kubonisiwe kulo mfanekiso ulandelayo.Ukuchaneka kuya kwanelisa kwaye kuya kufumaneka ngokulula xa kugqityiwe.

2) Ukuze ugqibezele ukucutshungulwa kwe-workpiece ngexesha elinye, i-embryo enqabileyo kufuneka ibe nesithuba sokudibanisa kunye nesibonelelo sokusika.

3) Okokuqala, emva kokunyangwa kobushushu, ukufudumala, kunye nokubumba, ukuqina kwe-embryo yoboya yi-HRC28-30 (ngaphakathi koluhlu lomatshini).

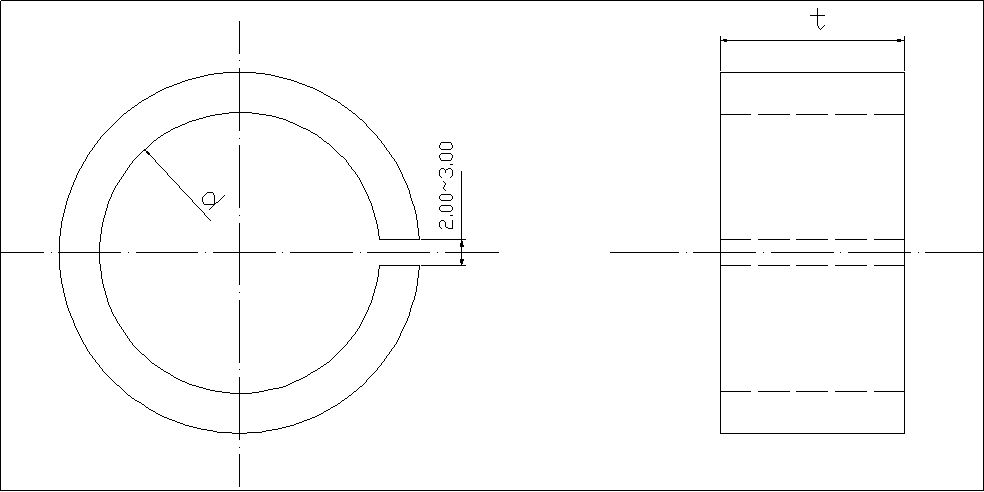

4) Isixhobo sokujika yiC620.Okokuqala, beka iziko langaphambili kwikhowuni yokusonta ukulungiselela ukulungiswa.Ukuze kuthintelwe ukuguqulwa kwesixhobo sokusebenza xa ubamba umkhono obhityileyo, umkhono ovulekileyo we-loop wongezwa, njengoko kubonisiwe kulo mfanekiso ulandelayo.

Ukuze kugcinwe imveliso yobuninzi, enye isiphelo somsesane ongaphandle weqokobhe elibhityileyo licutshungulwa kubukhulu obufanayo d, irula icinezelwe nge-axially, kwaye iqokobhe elibhityileyo liyacinezelwa xa ujikelezisa umngxuma ongaphakathi ukuphucula umgangatho. kwaye ugcine ubungakanani.Ukuqwalasela ubushushu bokusika, kunzima ukuqonda ubungakanani bokwandiswa kwendawo yokusebenza.Ulwelo olwaneleyo lokusika luya kujovwa ukunciphisa i-thermal deformation ye-workpiece.

I-5) Gxuma i-workpiece kunye ne-othomathikhi egxininisekileyo ye-jaw chuck emithathu, ujikeleze isiphelo sobuso, kunye nomatshini ongcolileyo kwisangqa sangaphakathi.Isibonelelo sokugqiba ukugqiba yi-0.1-0.2mm.Faka indawo yokugqiba isixhobo sokuguqula ukucubungula isibonelelo sokusika ukuhlangabezana neemfuno zokuphazamiseka kokuphazamiseka kunye noburhabaxa be-shaft yokukhusela.Susa isixhobo sokuguqula umngxuma wangaphakathi, faka i-shaft yokulinda kwiziko langaphambili, uyibambe ngeziko le-tailstock ngokweemfuno zobude, buyisela isixhobo sokuguqula i-cylindrical ukuba sibe rhabaxa kwi-excircle, uze ugqibe ukujika ukuhlangabezana neemfuno zomzobo.Emva kokugqithisa ukuhlolwa, sebenzisa ummese wokusika ukusika ngokobude obufunekayo.Ukuze wenze ukusika kube lula xa i-workpiece inqanyuliwe, i-cutting edge iya kuthatywa kwaye iphantsi ukuze wenze ubuso bokuphela kwendawo yokusebenza;Inxalenye encinci ye-shaft yokulinda isetyenziselwa ukusika i-gap kwaye igaye encinci.I-shaft yokukhusela isetyenziselwa ukunciphisa i-deformation ye-workpiece, ukukhusela ukungcangcazela, kunye nokunqumla izizathu zokuwa kunye nokubetha.

Kukuqukwa

Indlela yokulungisa i-casing-walled engasentla ixazulula ingxaki yokuba i-casing-walled casing deformation okanye ubungakanani kunye neempazamo zemilo azikwazi ukuhlangabezana neemfuno.Ukuziqhelanisa kubonisa ukuba le ndlela inokusebenza kakuhle komatshini, kunye nokusebenza kakuhle, kwaye ifanelekile ukwenza iinxalenye zodonga olude kunye noluncinci.Ubungakanani kulula ukuyiqonda, kwaye imveliso yebhetshi iyasebenza ngakumbi.

Ixesha lokuposa: Sep-29-2022